Planetary Concrete Mixer with PLC Control System

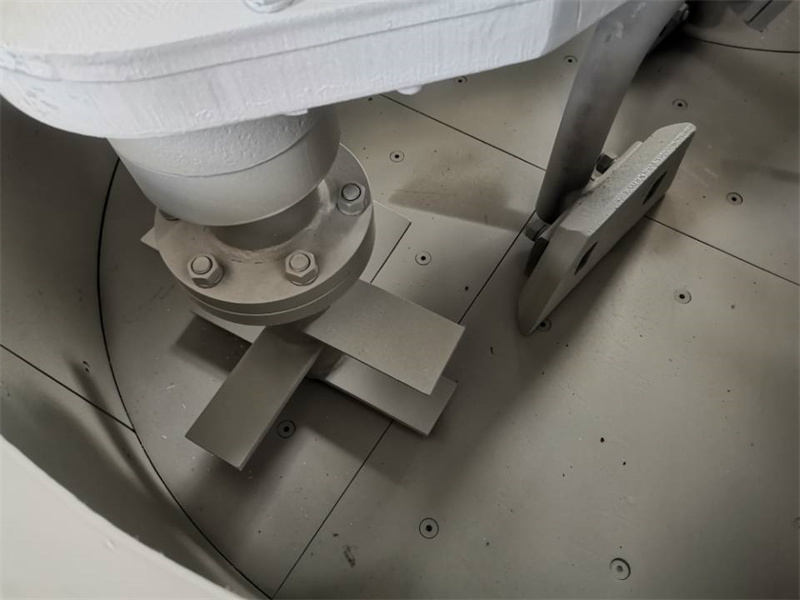

Planetary Concrete Mixer with PLC Control System is a professional mixer that mixes various materials such as cement, aggregate, water, and additives to produce high-quality concrete. Unlike traditional mixers, it features multiple arms that rotate around a central axis, ensuring thorough, consistent mixing.

The role of PLC control system:

The integration of a programmable logic controller (PLC) control system is what differentiates planetary concrete mixers from their traditional counterparts. This advanced technology automates the control and monitoring of the entire mixing process, increasing precision, efficiency and quality.

Key Features and Benefits:

1. Precise mixing: PLC control system enables precise measurement and proportioning of materials, ensuring consistent mixing for optimum strength and durability. This feature is especially important for large construction projects where consistency is critical.

2. Time and cost efficiency: Automated control systems significantly reduce manual labor and minimize human error. With preset mixing programs and adjustable parameters, the mixer optimizes the mixing process, saving time and costs associated with rework or adjustments.

3. Customizable mixing programs: The PLC control system allows the operator to create and save multiple mixing programs, tailored to specific project requirements. This flexibility enables the mixer to handle various types of concrete mixtures, including self-compacting, high-strength or fiber-reinforced concrete.

4. Real-time monitoring: PLC control system can monitor key parameters such as mixing time, speed, temperature and consistency in real time. Operators can easily track and adjust these variables to ensure the desired quality and consistency of the concrete mix.

5. User-friendly interface: The control panel of the mixer has an intuitive and user-friendly interface, allowing the operator to easily navigate and control the mixing process. In addition, the system can generate reports and logs for comprehensive data analysis and quality control.

Applications and Industry Impact:

The planetary concrete mixer with PLC control system can be applied to various construction projects, including highways, bridges, dams and high-rise buildings. Its ability to deliver a consistent and high-quality concrete mix enhances the structural integrity and longevity of these structures. Additionally, the efficiency and precision of the technology can help reduce material waste and increase the sustainability of the construction industry.

Planetary concrete mixers with PLC control systems represent a major advance in concrete mixing technology. Its ability to automate and optimize the mixing process, combined with its precision and versatility, make it a valuable asset in the construction industry.