Attractive Appearance refractory gunite machinery

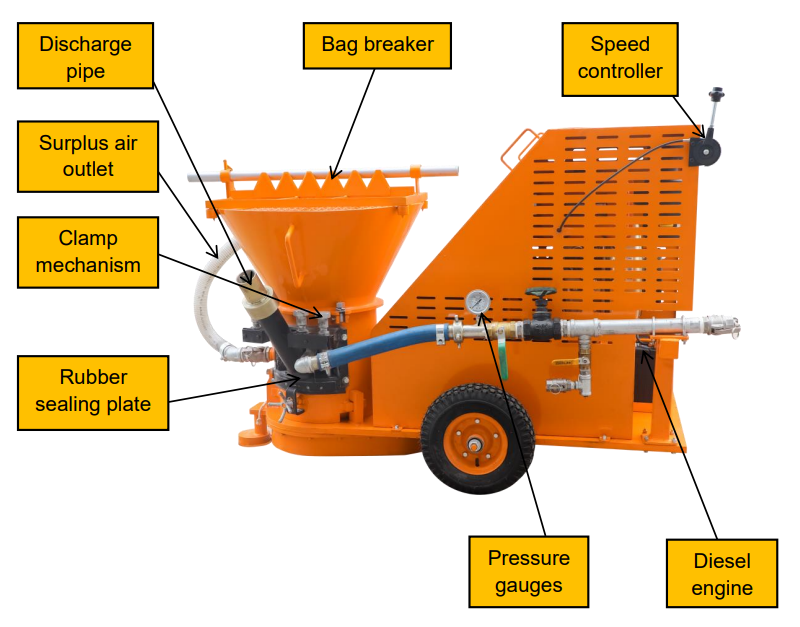

Parts of refractory gunite machinery – sealing plate and rotating lining board are the key components of refractory shotcrete machine. Be sure to pay attention to their maintenance to ensure that they will not fail during work.

What daily maintenance should we do for the attractive appearance refractory gunite machinery?

1. Parts of refractory gunite machinery – sealing plate and rotating lining board are the key components of refractory shotcrete machine. Be sure to pay attention to their maintenance to ensure that they will not fail during work.

2. The anti-sticking material cavity and discharge elbow have an anti-sticking function, and generally they will not stick during work, but the rotor should be opened after each shift, and the elbow should be checked and cleaned.

3. Always pay attention to the maintenance and maintenance of the shotcrete reducer:

a. After each shift, the mixture and other debris adhering to the outer surface of the reducer should be cleaned up in time;

b. Observe the oil mark frequently, and fill it in time when the lubricating oil is insufficient. The lubricating oil is the industrial gear oil.