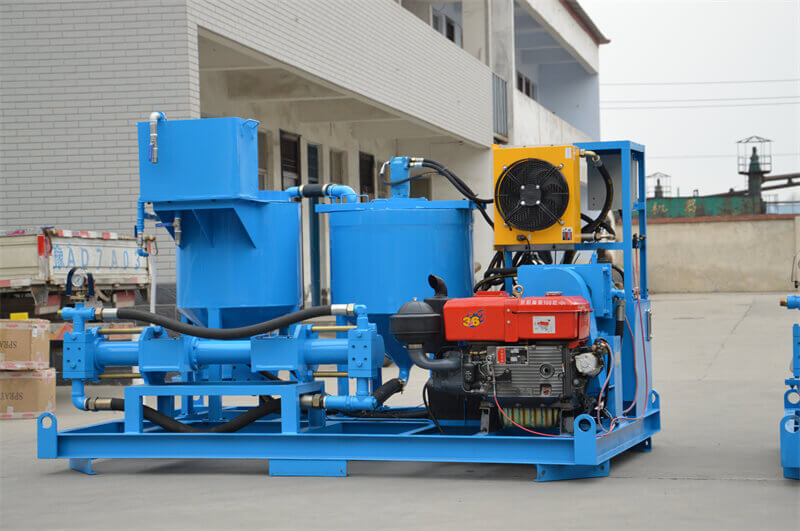

Customizable Grouting Rig with Pump for Tailored Grouting Applications

In construction, the use of state-of-the-art machinery and equipment is critical to increasing efficiency and ensuring project success. Customizable Grouting Rig with Pump for Tailored Grouting Applications is an example of a popular multi-tool. This innovative device combines the power of a grout rig and a pump to provide a wide range of applications in a variety of construction projects.

In construction, the use of state-of-the-art machinery and equipment is critical to increasing efficiency and ensuring project success. Customizable Grouting Rig with Pump for Tailored Grouting Applications is an example of a popular multi-tool. This innovative device combines the power of a grout rig and a pump to provide a wide range of applications in a variety of construction projects.

1. Foundation stability and soil consolidation:

One of the main applications of pump grouters is foundation stabilization and soil consolidation. The device is capable of injecting grout into the ground, filling voids and strengthening the soil, thereby ensuring a stable foundation for buildings. Whether repairing an existing foundation or reinforcing a new construction site, grout rigs with pumps play a vital role in improving the structural integrity and longevity of buildings.

2. Tunneling and mining operations:

In tunneling and mining operations, grouting rigs with pumps are important to prevent water ingress and maintain excavation stability. By injecting cement slurry into the rock formation, the equipment helps to strengthen the surrounding formation, minimizing the risk of collapse and ensuring a safe working environment. Additionally, it helps seal cracks and fissures, reducing water seepage and improving the overall efficiency of underground works.

3. Concrete Repair and Restoration:

The grouting machine with pump is widely used in concrete restoration and restoration projects. Whether filling cracks, voids, or repairing damaged concrete structures, this equipment provides precise and efficient solutions. The pumped grout not only strengthens the damaged area, but also improves the aesthetics and durability of the repaired concrete. From bridges to parking lots, grouters with pumps help extend the life of concrete structures.

4. Waterproof and leakproof:

Waterproofing is a key aspect of construction, especially in areas with high rainfall or high water tables. Pump grouting machine is an indispensable tool to prevent structure from leaking and waterproofing. Ensure the integrity and longevity of buildings by injecting grout into cracks, joints and other vulnerable areas to create a waterproof barrier. This application is particularly advantageous for basements, underground car parks and swimming pools.

5. Infrastructure repair:

Pumped grouters are also widely used in infrastructure restoration projects. Whether it’s bridges, dams or tunnels, aging infrastructure often requires reinforcement and repair. The device’s ability to inject grout into voids and cracks helps restore the structural integrity of these assets, extending their life and minimizing the need for costly replacements.

Grouting machines with pumps have revolutionized the construction industry by providing versatile and efficient solutions to a variety of construction challenges. From stabilizing foundations and consolidating soil to repairing concrete and preventing water ingress, the equipment has become an indispensable tool for contractors and engineers. By employing a pumped grouter, construction projects can be completed more efficiently, with enhanced structural integrity and reduced maintenance costs. If you have any different views or questions, please contact us!