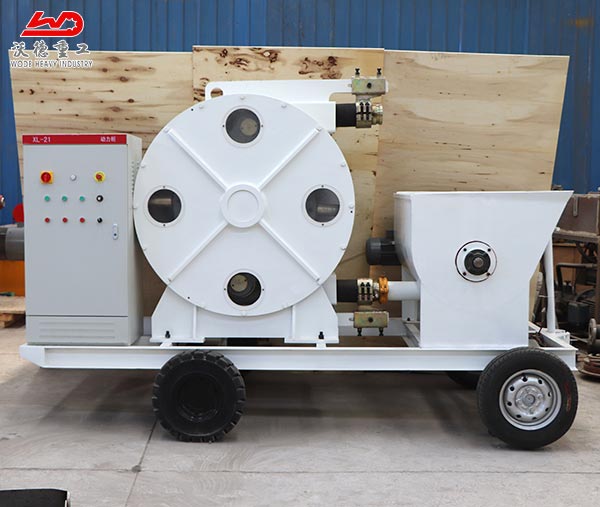

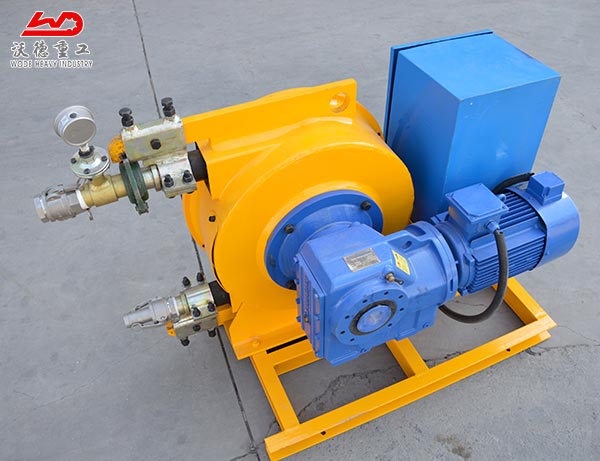

industrial hose pump for conveying mud and cement

In recent years, the development and application of various new materials is an important factor driving the development of industrial hose pump technology. A variety of new materials are used in the parts of the hose pump, and the benefits are mainly to extend the service life and reliability of the hose pump in corrosive media and to expand the scope of use of the industrial hose pump for conveying mud and cement.

In recent years, the development and application of various new materials is an important factor driving the development of industrial hose pump technology. A variety of new materials are used in the parts of the hose pump, and the benefits are mainly to extend the service life and reliability of the hose pump in corrosive media and to expand the scope of use of the industrial hose pump for conveying mud and cement. At the same time, coating technology and material surface treatment technology have become increasingly important in improving the flow characteristics, corrosion resistance, and wear resistance of hose pumps, and have broad application prospects.

The first priority for designers and users of an industrial hose pump for conveying mud and cement is its ability to deliver highly abrasive media. The industrial hose pump for conveying mud and cement has no valve and no seal, the only part in contact with the medium is the inner cavity of the rubber hose, and the rotor of the compressed hose is completely independent of the medium.