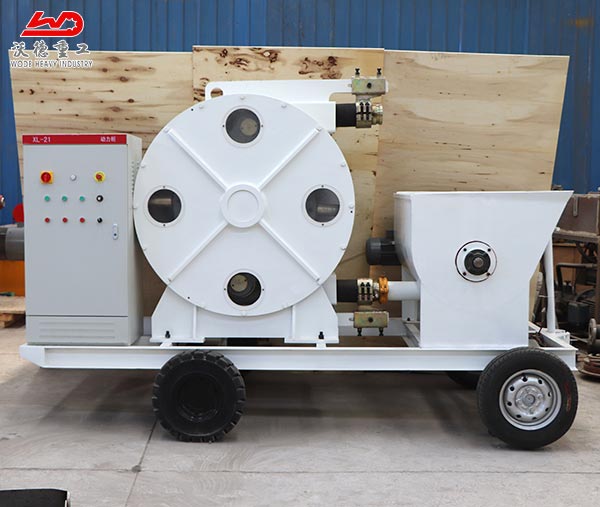

Innovative Peristaltic Hose Pump for Chemical Handling

Innovative Peristaltic Hose Pump for Chemical Handling operate on a unique mechanism that involves compressing and relaxing a flexible hose to create a pumping action. The pump rotor, fitted with rollers or slippers, presses the hose against the pump casing, creating a positive displacement effect. As the rotor rotates, the compression section moves along the hose, pushing the fluid forward. Once the pressure is released, the hose returns to its original shape, creating a vacuum that draws in more liquid. This peristalsis ensures a constant flow rate and prevents any backflow.

Innovative Peristaltic Hose Pump for Chemical Handling operate on a unique mechanism that involves compressing and relaxing a flexible hose to create a pumping action. The pump rotor, fitted with rollers or slippers, presses the hose against the pump casing, creating a positive displacement effect. As the rotor rotates, the compression section moves along the hose, pushing the fluid forward. Once the pressure is released, the hose returns to its original shape, creating a vacuum that draws in more liquid. This peristalsis ensures a constant flow rate and prevents any backflow.

Advantages of peristaltic hose pumps:

1. Gentle fluid handling: Peristaltic pumps offer gentle fluid handling capabilities, making them suitable for transferring shear-sensitive or fragile fluids. The absence of valves and seals minimizes the risk of contamination or damage to the fluid being pumped.

2. Self-priming and dry-running: Peristaltic hose pumps are self-priming, which means they can start pumping without additional priming. Additionally, they can run dry without damaging the pump, making them ideal for applications where dry running is an occasional possibility.

3. Excellent metering accuracy: The peristaltic hose pump provides precise metering capability because the flow rate is directly proportional to the pump speed. This precision is critical in applications that require precise dosing or mixing of fluids.

4. Minimal maintenance: There is only one wearing part for the hose and peristaltic pump, requiring minimal maintenance. Hoses can be changed quickly and easily, reducing downtime and overall maintenance costs.

Applications of peristaltic hose pumps:

1. Chemical industry: Peristaltic hose pumps are widely used in the chemical industry to transport corrosive chemicals, acids and alkalis. Their ability to handle abrasive fluids and maintain the integrity of the fluid being pumped makes them an ideal choice.

2. Food and beverage industry: The gentle suction action of the peristaltic hose pump is particularly beneficial in the food and beverage industry. They are commonly used to transfer viscous liquids such as syrups, sauces and dairy products without compromising their quality.

3. Pharmaceutical and Biotechnology: Peristaltic hose pumps are widely used in pharmaceutical and biotechnology applications due to their ability to handle sensitive and shear sensitive fluids. They are ideal for filling, sampling, and transferring a wide variety of fluids, including cell cultures, media, and reagents.

4. Water and wastewater treatment: Peristaltic hose pumps play a vital role in the water and wastewater treatment process. They are used to add chemicals, transfer sludge, and handle abrasive or corrosive fluids encountered in these applications.

The gentle fluid handling capabilities, self-priming characteristics, metering accuracy, and minimal maintenance requirements of peristaltic hose pumps make them an attractive choice. Whether in the chemical, food and beverage, pharmaceutical or water treatment sectors, peristaltic hose pumps continue to prove their worth as a reliable pumping technology.