Refractory Construction Gunning Machine

Traditionally, the installation of refractory materials is a labor-intensive and time-consuming process, which usually involves manual application methods, such as casting or manual ramming. However, with the development of technology, the Refractory Construction Gunning Machine appeared in the refractory industry. Fire-resistant gunning machine, also known as fire-resistant shotcrete machine, is a special equipment for spraying fire-resistant materials efficiently and accurately. The working principle of the machine is to mix the refractory with water, and then pump it to the nozzle through the hose, where the refractory is pushed to the surface to be lined at high speed.

Refractory materials are essential in various industries, such as steel, cement and petrochemical, where high temperature and harsh conditions are common. These materials are used as the inner walls of furnaces, boilers and other high-temperature equipment to provide heat insulation and protection against extreme high temperature and chemical corrosion. The installation of refractory is a key and challenging task, which requires precision and efficiency to ensure the life and performance of equipment.

Traditionally, the installation of refractory materials is a labor-intensive and time-consuming process, which usually involves manual application methods, such as casting or manual ramming. However, with the development of technology, the Refractory Construction Gunning Machine appeared in the refractory industry. Fire-resistant gunning machine, also known as fire-resistant shotcrete machine, is a special equipment for spraying fire-resistant materials efficiently and accurately. The working principle of the machine is to mix the refractory with water, and then pump it to the nozzle through the hose, where the refractory is pushed to the surface to be lined at high speed.

One of the main advantages of using a refractory gunning machine is that it can reach difficult and inaccessible areas, such as the top of a furnace or the wall of a large industrial container. The flexibility and operability of the machine make it possible to apply refractories in areas that are difficult or inaccessible by traditional methods. This not only improves the quality and integrity of the refractory lining, but also improves the overall safety and efficiency of the installation process.

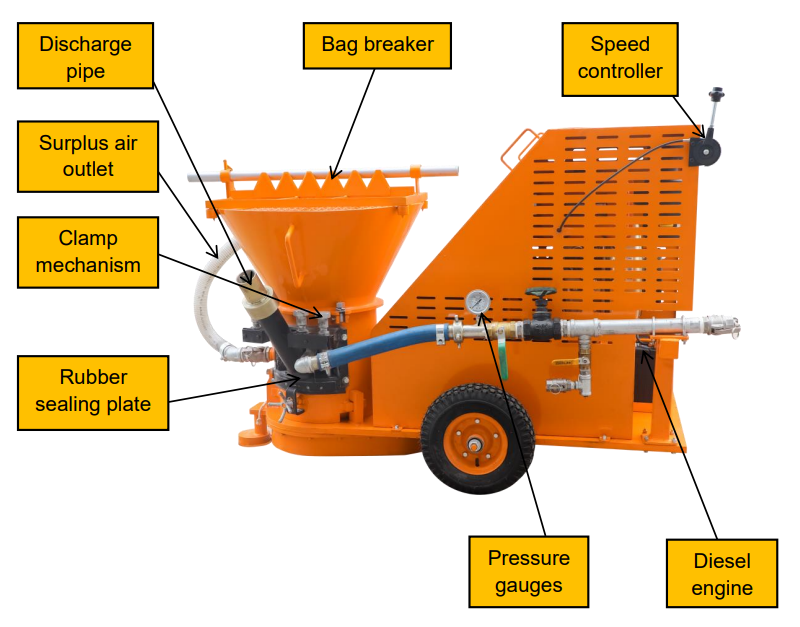

In addition, the refractory gunning machine is equipped with advanced functions and controls, allowing accurate and consistent application of refractory materials. This ensures that the lining is uniform and defect-free, which is very important for the performance and life of refractories. In addition, the use of fire-resistant gunning machine reduces material waste and dust emission, which helps to create a cleaner and more sustainable working environment.

The efficiency, accuracy and versatility of refractory gunning machine make it an indispensable tool in refractory industry, and it has obvious advantages in time, cost and quality.