WGP250/700/75PI-E Grout Inject Station for Tunnel Grouting Work

Description:

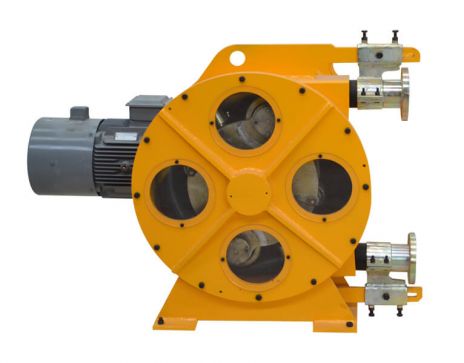

WGP250/700/75PI-E grout inject station for tunnel grouting work is a combination of mixer, agitator and grout pump in the base frame of efficient type grouting equipment.

Tunnel grout inject station compact structure, stable performance, pressure adjustable displacement, small volume, light weight, easy disintegration handling characteristics, can be in the construction site to replace fresh water pump, sewage pump, mud pump, widely used in Tunnel excavation and maintenance, roads, Bridges, DAMS, mine construction and the foundation of high-rise building and all kinds of grouting engineering.

High speed vortex mixer ensures mix quickly and evenly. Water, cement or bentonite is quickly mixed into a homogeneous slurry.

Then the mixed slurry was delivered to the agitator. Grout pump injects from the mixing drum (storage tank).

This ensures a continuous mixing and grouting operations. The grouting plant is hydraulic drive with electric motor.

Grouting pressure and displacement is adjustable. Compact size and it is easy to operate. It also takes up a small space.

Features

1. Ballvalve.

2. WGP250/700/75PI-E grout inject station for tunnel has hydraulic drive.

3. Up to 5mm particle size.

4. Grout injection station single piston and two-acting.

5. Tunnel grout inject station for tunnel is low flow pressure surge system.

6. Vertical type pump with compact size.

7. Grout injection station has high-speed colloidal grout mixer.

8. Lower charging material height for mixer.

9. Safely releasing pressure when pumping block.

10. Injection station has one and two-oil gear pump to get large output and high pressure in one pump.

Detail of the grout inject station:

|

cement mixer and agitator |

cement mixer and agitator details |

drilling cement grout mixer |

Technical Paremeter

|

Description |

Data |

|

Grout Station model |

WGP250/700/75PI-E |

|

Dimensions |

2710*1100*1820mm |

|

Weight |

1060kg |

|

Mixer |

|

|

Capacity |

250L |

|

Recycling Pump |

1100L/min |

|

Motor Power |

7.5Kw |

|

Rated Rev |

1450rpm |

|

Suitable water/cement ratio |

≥0.5:1 |

|

Agitator |

|

|

Capacity |

700L |

|

Rated Rev. |

36rpm |

|

Motor Power |

1.5KW |

|

Pump(vertical compact hydraulic grout pump, two oil gearbox) |

|

|

Pressure / Output |

High speed: 0-100bar 0-40L/min Low speed: 0-50bar 0-75L/min |

|

Power |

7.5kw |

Application

WGP250/700/75 PI-E grout inject station for tunnel grouting work is widely used in tunnel excavation and maintenance, road, bridge, dam, mine construction and foundation treatment of high-rise buildings and all kinds of grouting construction projects.

Civil engineering-dam, tunnel, subway, mine, soil nailing wall, curtain, anchor, cable trench and anchor grouting.

Grout inject station for tunnel can also be used in building structure-building and bridge repair, foundation reinforcement, slope support, soil compaction, rock grouting.

WGP250/700/75 PI – E grout inject station can also be used in engineering-underwater foundation, offshore platform, coast foundation grouting reinforcement

Tunnel grout inject station can be use in mine application-roadway reinforcement, backfill, waterproof grouting.

INQUIRY

Zhengzhou Wode Heavy Industry Co., Ltd.

-

Mobile Phone: +86-19913803800 -

E-mail: sales@wodetec.com -

Skype: Wode Equipment -

WhatsApp/Viber/Wechat: +86-19913803800 -

Tel: +86-371-55950656 -

Add: 20 Chuangyeavenue, GaoshanTown Industry Zone, Xingyang City, Zhengzhou, Henan Province, China

INQUIRY

If you have any questions, feedback or comments, please fill out the form below and we will reply you back as soon as possible.

HOT PRODUCTS

E-mail: sales@wodetec.com Consult

.jpg)